barnes reloading manual

Barnes reloading manuals are essential resources for precision ammunition crafting, offering detailed data for optimal performance. They provide crucial load data,

specifically tailored for Barnes’ unique bullet designs, ensuring accuracy and safety for dedicated reloaders.

Historical Overview of Barnes Bullets

Barnes Bullets emerged in the 1960s, initially focusing on high-quality, jacketed lead core bullets. Founder Randy Brooks sought to improve bullet performance through innovative designs, quickly gaining recognition for accuracy and reliability. A pivotal moment arrived with the introduction of the X-Bullet – a solid copper bullet designed for deep penetration and weight retention, revolutionizing hunting ammunition.

This innovation led to the development of the Triple-Shock X (TSX) bullet, combining a lead core with a copper jacket, offering expanded and deep penetration. Later came the Tipped Triple-Shock X (TTSX) and LRX bullets, further refining performance. Barnes’ commitment to monolithic, all-copper bullets established them as a leader in premium ammunition components, influencing reloading practices and data development, documented extensively in their reloading manuals.

Importance of Reloading with Barnes Data

Reloading with Barnes data is paramount due to the unique characteristics of their bullets. Unlike traditional jacketed bullets, Barnes’ monolithic or copper-jacketed designs behave differently under pressure and require specific load recipes. Utilizing data from Barnes’ reloading manuals ensures safe and optimal performance, maximizing accuracy and terminal ballistics.

Generic reloading data can lead to inconsistent results, potential safety hazards, or suboptimal performance with Barnes bullets. Their manuals provide precise powder recommendations, primer suggestions, and seating depth guidelines tailored to each bullet weight and cartridge combination. Following Barnes’ data guarantees reliable ignition, consistent velocities, and the intended expansion and penetration, crucial for hunting and precision shooting applications.

Understanding Barnes Bullet Technology

Barnes bullets utilize monolithic construction or specialized copper jackets, delivering exceptional weight retention and controlled expansion for superior terminal performance and accuracy.

Barnes TTSX Bullets: Design and Features

Barnes TTSX (Triple-Shock X) bullets represent a significant advancement in bullet technology, renowned for their all-copper construction. This monolithic design eliminates jacket/core separation, ensuring nearly 100% weight retention upon impact. The TTSX features an expanded diameter nose, initiating a rapid, aggressive expansion with large, symmetrical mushrooming.

This design maximizes energy transfer and creates devastating terminal performance, even at lower velocities. The bullet’s sharp, pointed profile promotes excellent ballistic coefficients for flatter trajectories and reduced wind drift. TTSX bullets are ideal for a wide range of hunting applications, offering exceptional accuracy and reliability. They are a premium choice for reloaders seeking consistent, ethical harvests.

Barnes LRX Bullets: Design and Features

Barnes LRX (Long Range X) bullets are specifically engineered for extended-range shooting and hunting, prioritizing accuracy and ballistic efficiency. Like the TTSX, the LRX boasts a monolithic, all-copper construction, guaranteeing exceptional weight retention and reliable expansion. However, the LRX features a more streamlined profile and a slightly longer, pointed nose.

This aerodynamic design significantly enhances ballistic coefficients, minimizing drag and maximizing downrange velocity. The LRX’s design also promotes stability in flight, resulting in tighter groupings at extreme distances. They are an excellent choice for magnum cartridges and rifles capable of achieving high velocities, delivering flat trajectories and terminal performance on distant targets.

Barnes TSX Bullets: Design and Features

Barnes TSX (Triple-Shock X) bullets represent a cornerstone of Barnes’ bullet technology, renowned for their devastating terminal performance. These bullets feature a unique all-copper construction, eliminating the need for traditional jacketed lead cores. This monolithic design ensures nearly 100% weight retention upon impact, maximizing energy transfer to the target.

The TSX’s design incorporates deep-penetrating grooves that initiate rapid expansion, creating multiple wound channels. This results in a larger, more lethal wound cavity, even on tough game animals. TSX bullets are suitable for a wide range of calibers and hunting applications, offering reliable and ethical performance in diverse conditions. They are a popular choice for hunters seeking maximum stopping power.

Key Components of a Barnes Reloading Manual

Barnes Reloading Manuals contain detailed cartridge data, powder recommendations, and primer selection guides, all meticulously organized for safe and accurate reloading practices.

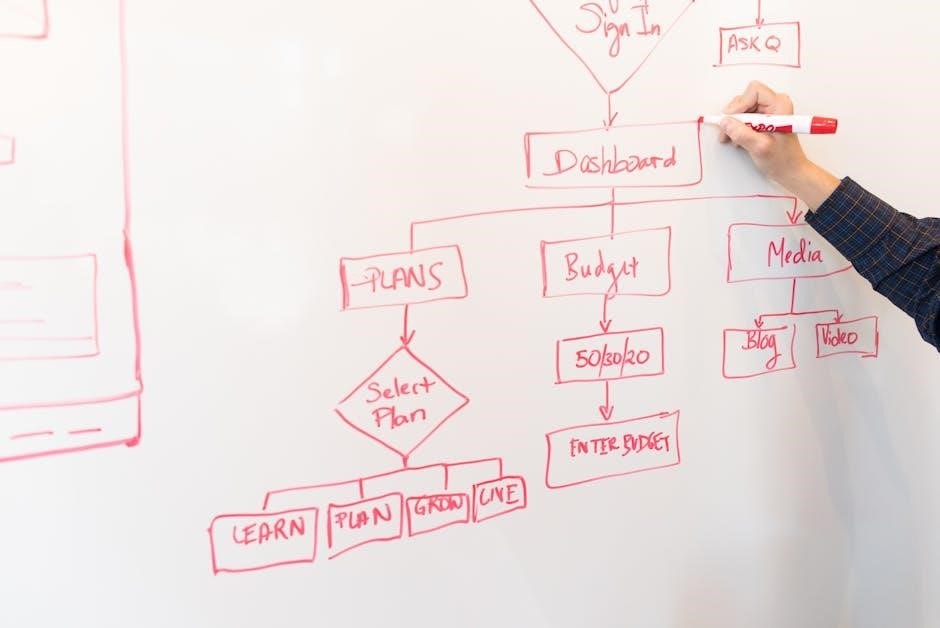

Cartridge Specific Data Tables

Barnes Reloading Manuals dedicate substantial sections to cartridge-specific data tables, forming the core of their reloading guidance. These tables aren’t simply lists; they are meticulously researched compilations offering a range of powder charges paired with specific Barnes bullet weights for each caliber.

Each entry within these tables typically includes starting, maximum, and often, suggested optimal loads. Crucially, they detail expected velocities, alongside pressure metrics, allowing reloaders to understand the performance characteristics of each load.

The data is presented in a clear, tabular format, making it easy to cross-reference bullet type, powder brand, powder weight, and resulting ballistic performance. These tables are designed to provide a safe starting point, emphasizing the importance of working up loads carefully.

Powder Recommendations for Barnes Bullets

Barnes Reloading Manuals don’t just present load data; they offer insightful powder recommendations tailored to their bullet designs. Recognizing that Barnes bullets, particularly the all-copper varieties, behave differently than traditional jacketed bullets, the manuals suggest powders that consistently deliver optimal results.

These recommendations aren’t arbitrary. They stem from extensive testing, considering factors like burn rate, temperature sensitivity, and how well the powder complements the bullet’s construction. The manuals often highlight specific powder families – like Hodgdon, Alliant, or IMR – and pinpoint particular powders within those lines that perform exceptionally well.

Reloaders are encouraged to use these suggestions as a starting point, understanding that individual rifles and conditions may necessitate adjustments.

Primer Selection Guidelines

Barnes Reloading Manuals emphasize the critical role of primer selection in achieving consistent and accurate loads. While seemingly small, the primer initiates the entire combustion process, impacting velocity, pressure, and ultimately, accuracy. The manuals provide specific primer recommendations for each cartridge and bullet combination.

Generally, Barnes data often favors standard primers, though magnum primers may be suggested for certain loads or in colder temperatures to ensure reliable ignition. The manuals detail which primer types – Federal, CCI, Remington, etc. – have been tested and proven reliable with Barnes bullets.

Reloaders are cautioned against substituting primers without careful consideration, as this can significantly alter performance. Always adhere to the manual’s recommendations for optimal and safe results.

Reloading Data Interpretation

Barnes Reloading Manuals present data in clear charts, detailing powder charges, velocities, and pressures. Understanding these metrics is vital for safe and accurate reloading practices.

Understanding Ballistic Coefficients

Ballistic Coefficient (BC) is a crucial factor in long-range shooting, and Barnes Bullets often exhibit high BC values due to their streamlined designs and construction. A higher BC indicates the bullet’s ability to overcome air resistance, maintaining velocity and energy over extended distances.

Barnes Reloading Manuals provide the BC for each bullet weight and caliber, enabling accurate trajectory calculations using ballistic software or charts. Understanding how BC impacts bullet drop, wind drift, and overall trajectory is essential for precise shot placement. Different Barnes bullet designs, like TTSX and LRX, will have varying BCs, influencing load development for specific applications. Accurate BC data ensures reliable performance at various ranges.

Velocity and Pressure Considerations

Barnes Reloading Manuals meticulously detail safe velocity ranges and maximum average pressures (MAP) for each cartridge and bullet combination. Maintaining appropriate pressure levels is paramount for shooter safety and rifle longevity. Exceeding MAP can lead to dangerous conditions, while insufficient pressure may result in inconsistent performance.

Velocity directly impacts bullet trajectory and terminal performance. Barnes data provides starting loads and velocity expectations, allowing reloaders to fine-tune their recipes. Factors like barrel length, ambient temperature, and powder lot variations can influence velocity. Careful monitoring and adherence to published data are crucial. Always prioritize safety and consult the manual for specific guidelines regarding pressure and velocity.

Interpreting Load Data Charts

Barnes Reloading Manuals present load data in comprehensive charts, requiring careful interpretation. These charts typically include powder type, charge weight, overall cartridge length (OAL), and corresponding velocity figures. Understanding the units of measurement (grains, inches, feet per second) is essential. Barnes often provides a range of charges, with a starting load indicated for safety.

Pay close attention to case preparation notes and primer recommendations listed alongside the data. Variations in components can affect pressure, so consistency is key. The charts also often include notes on observed accuracy or potential issues. Always cross-reference data with your specific components and rifle. Thoroughly review all notes before proceeding with reloading, prioritizing safety and accuracy.

Safety Precautions in Barnes Reloading

Barnes reloading demands strict adherence to safety protocols. Proper case preparation, accurate powder measurements, and careful component selection are paramount for safe, reliable ammunition.

Proper Case Preparation

Thorough case preparation is foundational to safe and accurate Barnes reloading. Begin with a meticulous inspection for cracks, splits, or any signs of damage; discard any compromised cases immediately. Next, resizing the case to SAAMI specifications ensures proper chamber fit and extraction.

Cleaning cases, removing old primer residue and powder fouling, is crucial. Utilize a quality case tumbler with appropriate media. Primer pocket cleaning is also essential, removing stubborn residue to allow for consistent primer seating. Finally, uniform the flash hole to ensure reliable ignition. Consistent case length is vital; trim cases as needed to maintain uniformity. These steps minimize potential issues and maximize performance with Barnes bullets.

Safe Powder Handling Procedures

Prioritizing safety when handling powders is paramount in Barnes reloading. Always work in a well-ventilated area, free from ignition sources like open flames or sparks. Store powders in a cool, dry location, away from direct sunlight and heat. Never smoke or eat while handling powders.

Utilize dedicated powder scales and measures, ensuring they are clean and calibrated regularly. Double-check powder charges meticulously before seating bullets – a small error can have significant consequences. Avoid static electricity buildup by grounding yourself and your equipment. Never return unused powder to its original container to prevent contamination. Follow published load data precisely; do not substitute powders without expert guidance.

Importance of Accurate Measurements

Precision is key when reloading with Barnes bullets, and accurate measurements are non-negotiable. Consistent powder charges directly impact velocity, pressure, and ultimately, accuracy. Utilize a high-quality, calibrated scale capable of measuring powder to within 0.1 grains. Case length and primer seating depth also require precise measurement, influencing internal ballistics.

Always double-check measurements before proceeding. Small variations can lead to significant performance differences, potentially compromising safety. Consistent bullet seating depth is equally crucial for achieving optimal results. Employing accurate tools and meticulous technique ensures reliable and repeatable loads, maximizing the potential of Barnes bullet technology.

Advanced Reloading Techniques with Barnes Bullets

Experienced reloaders can fine-tune Barnes loads by optimizing seating depth and analyzing velocity extremes, achieving peak accuracy tailored to their specific rifle.

Optimizing Loads for Specific Rifles

Achieving peak accuracy with Barnes bullets necessitates tailoring loads to individual rifle characteristics. Each firearm exhibits unique preferences regarding powder burn rate, case capacity, and throat geometry.

Begin by establishing a baseline load using published data from Barnes manuals, then incrementally adjust powder charges in small increments – typically 0.1 to 0.3 grains – while meticulously documenting velocity and group size.

Pay close attention to pressure signs, and always stay within established safe limits.

Testing various seating depths can also significantly impact precision, as it alters the bullet’s engagement with the rifling.

Consistent testing, coupled with careful observation, unlocks the full potential of Barnes bullets within your specific rifle.

Effect of Bullet Seating Depth

Bullet seating depth profoundly influences both accuracy and pressure dynamics when reloading with Barnes bullets. Deeper seating reduces case capacity, potentially lowering velocity but increasing pressure. Conversely, shallower seating increases case capacity, potentially raising velocity but decreasing pressure.

Barnes manuals often provide starting seating depths as a guideline, but optimal depth varies by cartridge, bullet type, and rifle. Experimentation is key; incrementally adjust seating depth in small increments (0.010″ ⎼ 0.020″) and meticulously record results. Observe for pressure signs and monitor velocity changes. Finding the “sweet spot” maximizes harmonic resonance between the bullet and barrel, resulting in tighter groupings and improved consistency.

Analyzing Velocity Extremes

Velocity extremes – both high and low – are critical indicators of reloading consistency when using Barnes bullets. Significant variations suggest potential issues with powder measure settings, case preparation, or even primer inconsistencies. A tight velocity spread (e.g., under 10 fps) signifies a highly consistent load;

Barnes reloading manuals emphasize meticulous record-keeping. Documenting each shot’s velocity allows for identifying outliers and calculating standard deviation. Investigate any shots falling outside acceptable limits. Examine cases for signs of overpressure or improper seating. Consistent velocity is paramount for predictable ballistic performance and achieving optimal accuracy with Barnes’ premium bullets.

Resources and Further Information

Official Barnes manuals, online forums like those dedicated to reloading, and ballistic calculation tools provide extensive support for Barnes bullet reloading endeavors.

Official Barnes Reloading Manuals

Barnes Reloading Manuals represent the definitive source for accurate and safe load data when utilizing their premium bullets. These manuals aren’t simply collections of recipes; they are meticulously researched guides developed through extensive testing with Barnes’ proprietary bullet designs.

Each manual covers a wide range of cartridges, providing detailed tables outlining powder recommendations from various manufacturers, corresponding velocities, and pressure data. They emphasize the importance of adhering to published data for safety and optimal performance.

Barnes manuals often include specific guidance on case preparation, primer selection, and bullet seating depths tailored to maximize the ballistic potential of their TTSX, LRX, and TSX bullet lines. Investing in the appropriate Barnes manual is paramount for any serious reloader seeking consistent, reliable results.

Online Forums and Communities

Barnes reloading benefits greatly from the wealth of knowledge shared within online forums and communities dedicated to reloading and ballistics. Platforms like dedicated shooting forums and social media groups provide spaces for reloaders to exchange experiences, troubleshoot issues, and discuss specific load combinations with Barnes bullets.

These communities often feature detailed discussions on powder choices, primer sensitivities, and observed performance with various rifles. Experienced reloaders frequently share their optimized loads and insights, offering valuable perspectives beyond the data presented in manuals.

However, it’s crucial to exercise caution and verify information independently, always prioritizing safety and adhering to published load data as a starting point. Online resources supplement, but never replace, the authoritative guidance found in official Barnes Reloading Manuals.

Ballistic Calculation Tools

Barnes reloading is significantly enhanced by utilizing ballistic calculation tools. These software programs and online calculators allow reloaders to predict bullet trajectory, wind drift, and velocity at various distances, optimizing loads for specific shooting scenarios.

Inputting precise data – including Barnes bullet ballistic coefficients (BC), muzzle velocity derived from reloading data, and environmental factors – yields accurate predictions. Tools like Ballistic AE, or online options, help refine load development, accounting for atmospheric conditions and rifle characteristics.

While these tools are powerful, remember they rely on accurate input data. Always cross-reference predicted results with practical testing and prioritize safety guidelines outlined in Barnes Reloading Manuals for reliable performance.